Impact of Minimal Supplemental Heating on Winter High Tunnel Greens

Ethan Grundberg, Vegetable Specialist

Eastern New York Commercial Horticulture

With support from a Northeast Sustainable Agriculture Research and Education program (NE SARE) Partnership Grant (ONE17-298) and the generous cooperation of the Poughkeepsie Farm Project (PFP), I spent much of last winter gathering data from a side by side comparative trial assessing the impact of minimal heating in winter greens production. Specifically, we tracked yield, soil nitrate availability, total plant nitrogen uptake, propane use, and soil temperature all winter in the two identical side-by-side 42'x196' double layer inflated poly Harnois high tunnels at PFP. The only deliberately manipulated variable between the two tunnels was the minimum thermostat setting: one tunnel was set to 33° F ambient air temperature and the other set to 40° F.

You may ask, prior to considering the differences observed between the two temperature thresholds, why heat at all? There seems to be little agreement among winter greens growers regarding the true costs and potential value of using supplemental heat all winter. For the PFP, much of the decision to heat the tunnels is informed by the fact that no one lives on site, so using row covers inside of high tunnels for additional protection is not feasible. Additionally, using supplemental heat allows the PFP to grow more tender, but more efficient to harvest and higher value crops like Salanova lettuces throughout the winter instead of just the hardier winter greens. Using supplemental heat also provides the PFP with greater flexibility in timing harvests to meet market demand; there is no waiting around until the afternoon for crops to thaw. Finally, given the sheer size of the tunnels at PFP and high quality double layered and inflated plastic covers, the thought was that the size of the thermal sink combined with the improved insulation would make heating more economical than it might be in a smaller, less well insulated set up.

So, clearly, heating at all won't make infrastructural sense to all winter greens growers. However, here are some of the observations that came from the trials at PFP during the winter of 2017-18.

Temperature

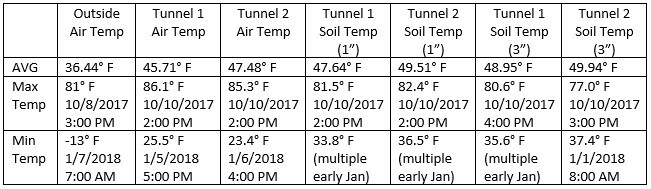

Tunnel 1 had the thermostat set to 33° F and Tunnel 2 had the thermostat set to 40° F. Both tunnels were set to begin incrementally opening their ridge vents at 60° F. Temperature sensors were situated in the tunnels at approximately 2" above ground level for inside air temperature recording. Each tunnel also had two soil temperature data loggers, one buried at 1" depth and one at 3" depth, in the planted beds. The table below shows the average temperatures recorded from each sensor for the period beginning October 6, 2017 and ending February 11, 2018.

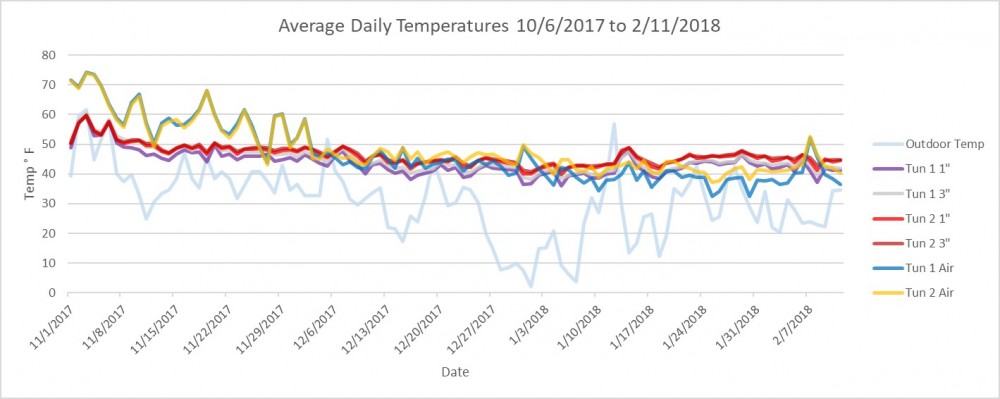

For the more visually inclined, here is a graph of the daily temperature averages for all of the sensors plus the outside air temperature.

Admittedly, that is a lot of temperature data to try to make sense of. Here are some salient observations for me:

- Temperatures inside of both tunnels did not fall low enough to trigger the heating systems to fire up until the week of November 13th. In fact, temperatures mostly remained above both thermostat thresholds until the beginning of December 2017.

- Neither tunnel's heating system (two propane-fueled overhead Modine 93 high efficiency heaters per tunnel) was able to keep up with the bitter cold, overcast skies, and high wind of early January as temperatures inside both Tunnel 1 and Tunnel 2 plummeted into the 20s.

- As expected, soil temperatures at both depths were much steadier over time compared to air temperatures. For most of the winter, soil temperatures at the same depth in Tunnel 1 and Tunnel 2 did not vary more than 3° F despite much larger air temperature differences.

- Setting the ridge vents to begin opening at 60° F definitely helped to regulate large temperature swings and keep humidity down. However, that same venting also very likely decreased temperature differences that may have otherwise been observed between the two tunnels.

Nitrogen Availability and Uptake

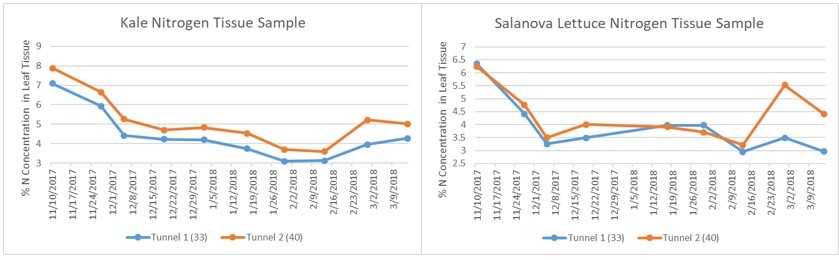

Soil nitrate availability tests were conducted every week through the winter. Plant tissue samples were submitted to Waters Agricultural Laboratories every other week through the winter for nutrient analysis. What lessons were learned from these data collected?

- As we always preach, nitrogen is so dynamic it is difficult to capture in snapshot tests. This is true even in the winter months when the soil microbes that drive the nitrogen cycle slow down. Soil nitrate levels were not significantly or consistently different between the two tunnels.

- More than just temperature influences nitrogen availability. Maintaining adequate soil moisture and, ideally, living roots in the high tunnel before planting is necessary to preserve the soil microbial community that makes nitrogen available for plant uptake.

- Based on the plant tissue nutrient analyses, fertilizing to 70 pounds/acre of nitrogen in September provided sufficient nitrogen to kale, spinach, and Salanova until mid-February in both of the tunnels.

- Targeted early spring fertigations with soluble Chilean nitrate carried those crops to maturity in early April (notice the quick response in total nitrogen content of leaf tissue after a February 15th fertigation of the equivalent of about 6.25 pounds nitrogen/acre). Planning to fertigate with soluble plant available nitrate in the late winter/early spring is likely a far more sustainable and responsible nutrient management plan for high tunnels than overcompensating for slowed nitrogen release with higher levels of front-loaded nitrogen.

Yield

Thanks to the diligence and cooperation of the entire crew at PFP, yield from sub-plots of curly kale, spinach, and lettuce within each tunnel were recorded throughout the winter. Unfortunately, the yield data is not particularly useful for analysis because of the incremental nature of the harvest (cut for order only, not the entire plot at a time) and because of serious disease pressure in the plots. Specifically, both lettuce and brassica powdery mildew decreased marketable yield unevenly between the tunnels and across varieties. More significantly, botrytis crown rot (Botrytis cinerea) of lettuce caused a serious decline in yield, especially after the first cut of Salanova. The botrytis crown rot was far more severe in Tunnel 1, likely because the tunnel had been used to grow tomatoes during the summer and had experienced a moderate level of botrytis ghost spot (also caused by Botrytis cinerea), giving the pathogen population an opportunity to grow year round.

That said, there was one important observation made between the two tunnels. The warmer tunnel (Tunnel 2) yielded three lettuce harvests in the same time that the cooler tunnel (Tunnel 1) yielded only two. Depending upon how much Salanova lettuce a grower may plant in a tunnel and what the market value for that lettuce is, it could make financial sense to heat to 40° F instead of 33° F for the added yield from a third cut of lettuce.

Propane Use

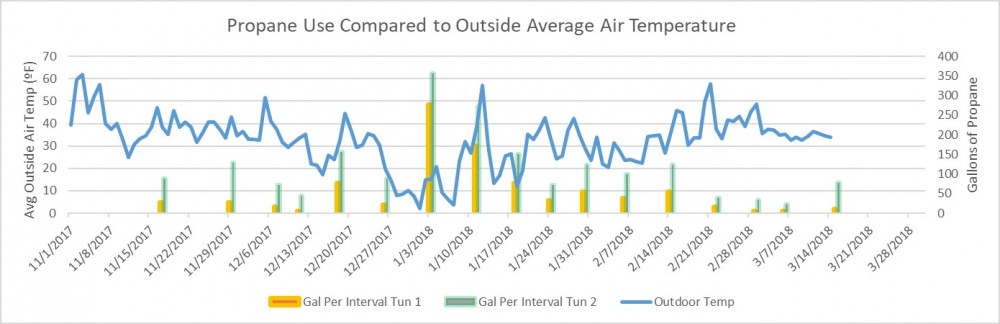

There is no real surprise here: heating a tunnel to 40° F uses a lot more propane than heating a tunnel to 33° F. It took 979 gallons of propane to heat the tunnel to 33° F from November through March. It took 2.1 times as much propane to add the extra 7 degrees to reach 40° F over the same period. Also not particularly surprising, the difference in propane use between the two tunnels was highest when outside air temperatures were in the mid-30s (thus resulting in the heaters in Tunnel 2 being activated, but not in Tunnel 1 with the thermostat set to 33° F). The following graph shows the total propane use in each tunnel for the previous week period on the bar graph compared to the average daily outdoor air temperature plotted as the blue line on the graph.

Need for Further Research

As is often the case with one-year trials, this study raised many more questions than it answered. First, if we had access to a research tunnel with supplemental heating and could sufficiently control pest and disease pressure, would we be able to replicate the observed yield difference in Salanova lettuce again? Would yield differences be more significant in kale and spinach under such conditions than they were at the PFP? What would be the potential impact of increasing temperature for shorter time intervals during the winter to push faster return growth on lettuce? Could analyzing impacts at more temperature thresholds, especially one just below freezing, help to narrow in on critical temperature thresholds to influence plant metabolic processes as well as nutrient availability? What is the interaction between heat and pests and diseases common in winter tunnel production? What is the ideal source and quantity of pre-plant nitrogen to apply for different greens crops and how does that change with supplemental heating? We are in the process of seeking more funding with the hopes of answering some of these questions in the future.

Upcoming Events

ASL 105 Employee Development and Training

November 17, 2025 : ASL 105: Employment Development and Training

ASL105: Employee Development and Training

Three leadership practices are essential for supervisors: setting clear expectations, employee training and development, and providing performance feedback.

In Employee Development and Training you will learn best practices to plan and conduct training that engages employees, supports retention, and helps ensure great quality work. You will also learn how to create a culture of continuous learning and performance improvement through employee development, coaching, and career planning. This is a 6-week online course, taught in English.

Topics include:

- Planning effective training programs

- Onboarding new employees

- On the job training

- Staff development

- Creating a culture for continuous learning

- Coaching and career planning

Course begins: Wednesday, November 12 Live Zoom discussions: Tuesdays, 3:00 PM - 4:00 PM ET beginning November 18 through December 23.

Registration closes November 17 at 5 PM ET.

Ag Labor Road Show IX

December 1, 2025 : Save the Date! - Ag Labor Roadshow Webinar 1

In addition to the in-person Ag Labor Roadshow program in our region on December 9, two webinars are scheduled for December 1 and December 22. Each webinar will focus on different program content that is different from the in-person sessions. These webinars are an added benefit to program registration.

December 9, 2025 : Save the Date - Ag Labor Road Show In-Person Event (Greenwich, NY)

Greenwich, NY

The Roadshow delivers essential updates on labor law, regulations, and workforce best practices—tailored for farm owners, managers, and ag service providers. Sessions also focus on practical strategies to boost communication, strengthen retention, and build a positive workplace culture.

The in-person session for Eastern NY is December 9 - Elks Lodge, Greenwich, NY - full day in person session

Additional in-person sessions are:

December 10 - Hilton Garden Inn, Watertown, NY, December 17 - Cornell AgriTech, Geneva, NY, December 18 - Genesee Community College, Batavia, NY

December 22, 2025 : Save the Date! - Ag Labor Roadshow Webinar 2

In addition to the in-person Ag Labor Roadshow program in our region on December 9, two webinars are scheduled for December 1 and December 22. Each webinar will focus on different program content that is different from the in-person sessions. These webinars are an added benefit to program registration.

How to Obtain a Pesticide Applicator License

December 17, 2025

Thinking about becoming a certified pesticide applicator in New York, but aren't sure where to start? Join DEC representative Kenneth Klubek for a discussion on who needs to become a certified pesticide applicator, certification types, examination procedures, and recertification. Participants will have ample opportunity to ask questions during the program.